Introduction

This guide will walk through the correct installation procedure for the Grimm OffRoad Tacoma Uniball Upper Control Arms.

Consumer Warning

All Grimm OffRoad products must be installed by a competent and qualified individual in accordance with the installation instructions intended for the product. Incorrectly installed products will void any warranties and may result in damage to the product or damage to the vehicle it was installed on. Read any provided instructions or guides and watch any available videos before attempting installation. If there are any questions, please contact Grimm OffRoad before starting installation.

Many products require the vehicle be properly raised and supported off the ground. The installer is responsible for confirming that this may be done in a safe manner and the correct equipment is available to perform the installation. Grimm OffRoad installation instructions assume the installer is able to properly and safely lift the vehicle.

Vehicles that have been modified will not perform the same as a stock vehicle. It is incumbent upon the owner of the vehicle to be aware of the differences the modifications will make to the driving characteristics of the vehicle. These may include (but are not limited to): changes in handling, braking, rollover angle, incompatibilities with the factory anti-lock braking systems, stability control systems, or traction control systems.

Notes

- These upper control arms are designed with additional caster over stock, in order to improve drive-ability, especially in cases where the vehicle has been lifted over stock height. It is important that when the vehicle is taken to be aligned that the alignment technician is familiar with modified vehicles and does not simply try to match the factory alignment settings.

- It is recommended that these control arms are used in conjunction with the Grimm OffRoad Billet Uniball Cap Set, part number 10019, in order to increase the longevity of the uniballs.

Tools

Parts

- Left Tubular UCA (Driver)

- Right Tubular UCA (Passenger)

- 2.125 x .565 x .188 Washer × 8

- Taper Adapter × 2

- Bearing Cap (.500 ID) × 2

- 1.00 x .563 x 2.060 Pivot Sleeve × 4

- 1.625 x 1.000 x .850 Hat Bushing × 8

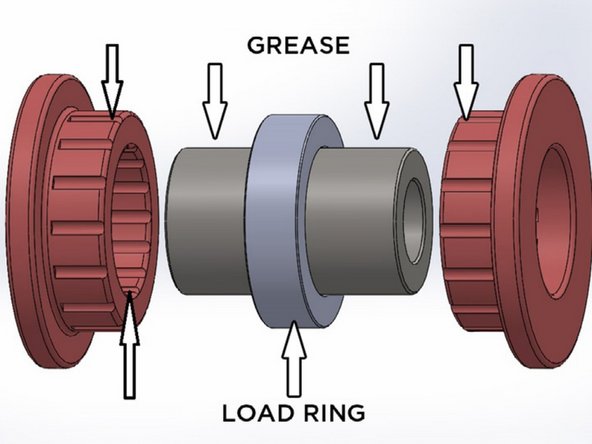

- 1.590 x 1.005 x .250 Load Ring × 4

- 1/2-20 x .875" 12 Point Flanged Cap Screw × 2

- 9/16-18 Nylock Nut × 2

- 9/16 F436 Flat Washer × 2

- Red Threadlocker

-

-

Park the vehicle on a flat, level surface. Make sure the vehicle is in park or in gear, and that the parking brake is set. Raise the front of the vehicle and support the frame with jackstands.

-

Remove front wheels.

-

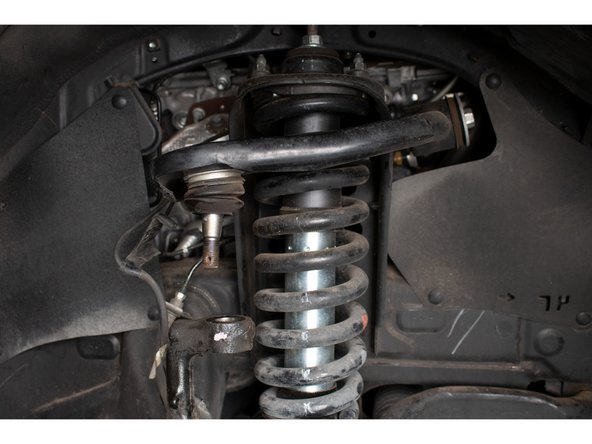

Place a jack under the lower ball joint and slightly raise the spindle so that the suspension is not at full droop.

-

-

-

Remove the ABS line that is routed along the top of the control arm with a 10mm socket or wrench.

-

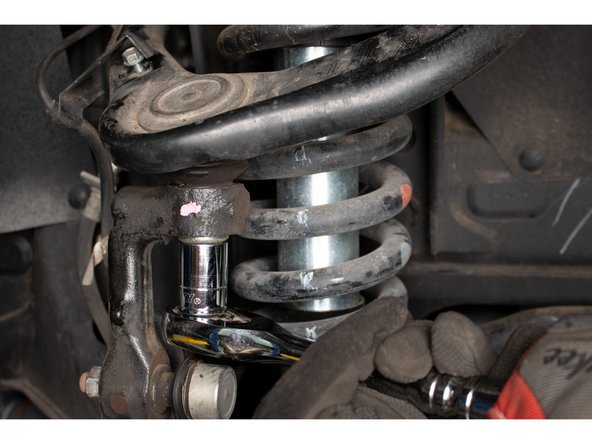

Using a 19mm socket and/or wrenches, loosen the large upper control arm pivot bolt, but do not remove yet.

-

Remove the cotter pin from the upper ball joint stud.

-

-

-

Using a 19mm socket or wrench, loosen the upper ball joint nut. Do not remove the nut, leave a few threads engaged.

-

Strike the spindle with a large hammer where the upper ball joint stud engages the spindle. A couple quick strikes should separate the taper. Alternatively, a ball joint separator may be used.

-

Support the spindle so that it does not over extend the CV joints when detached.

-

Remove the castle nut from the upper ball joint after the ball joint taper has been separated from the spindle.

-

The upper control arm will have some bushing preload and will want to 'pop' up.

-

-

-

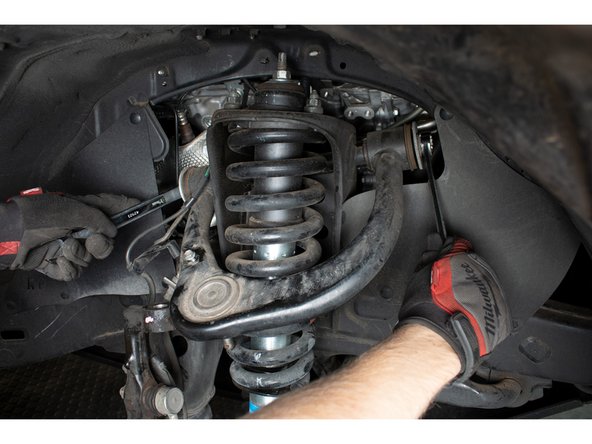

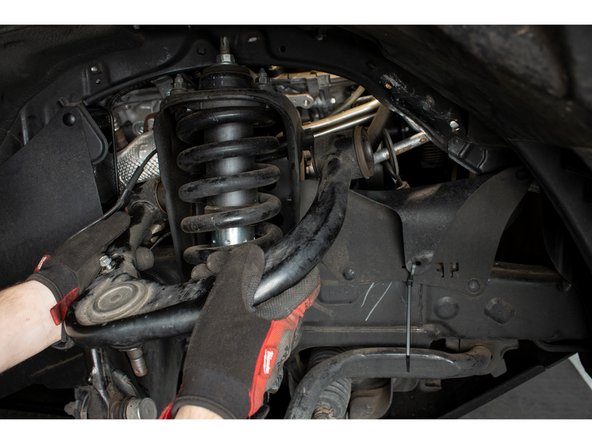

Using a 19mm socket and/or wrenches, remove the nut and washer from the rear side of the long pivot bolt. Carefully feed the bolt forward until it clears the front of the A-arm.

-

It will be necessary to bend the body sheet metal slightly in order to remove the bolt. A pair of channel locks or a crescent wrench will help accomplish this. Take your time and work around the wire harness and AC lines behind the body sheet metal.

-

With the upper control arm pivot bolt out, remove the stock upper control arm.

-

-

-

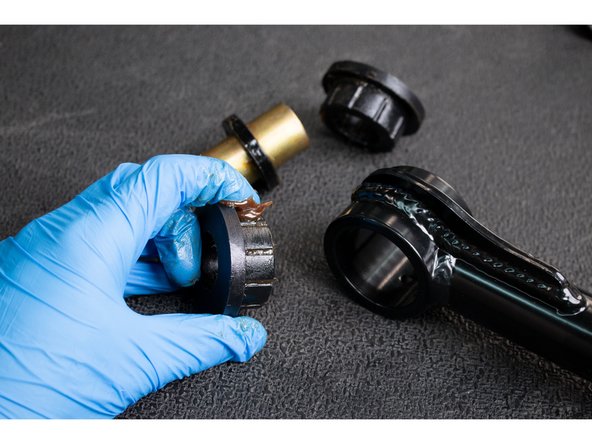

Apply grease to the inside of the Load Rings and slide them on to the Pivot Sleeves. They should sit in the center of the Pivot Sleeves.

-

Apply grease to the inside of the upper control arm pivot tubes and insert the Pivot Sleeves with Load Rings into the arms.

-

Apply grease to the inside and outside of the Hat Bushings, and slide them into the upper control arm pivot tubes.

-

Make sure the Hat Bushings are fully seated in the control arms, if they become too tight to push in, check to make sure the Pivot Sleeves are aligned properly. If the bushings are still too tight of a fit, use a large pair of pliers or a vice to fully seat the bushings, being very careful not to tear them.

-

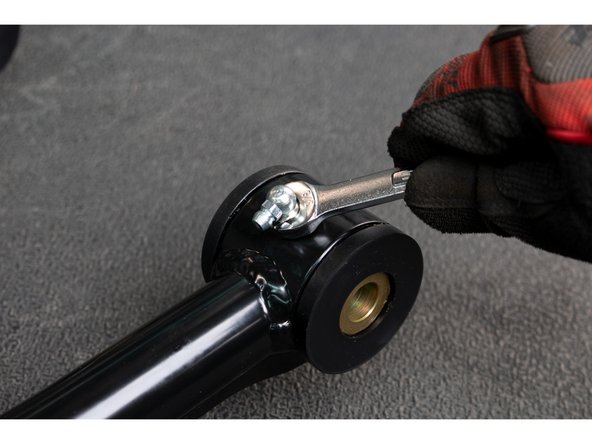

Install the supplied zerk fittings using a 5/16" wrench. Do not overtighten!

-

-

-

Install the taper adapter up from the bottom into the uniball. The tapered pin should point down, towards the spindle.

-

Place the domed top cap on top of the uniball and hand thread in a 12 point 1/2-20 cap screw.

-

-

-

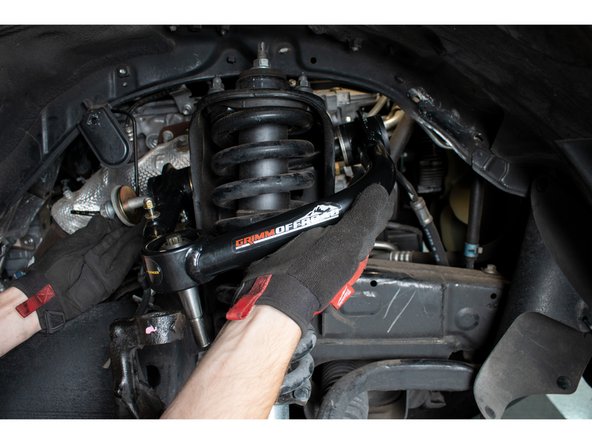

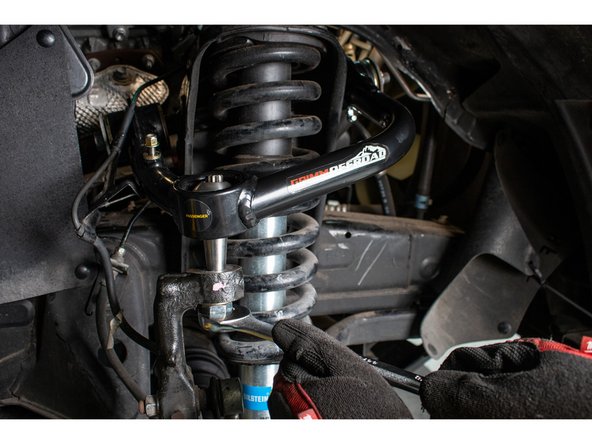

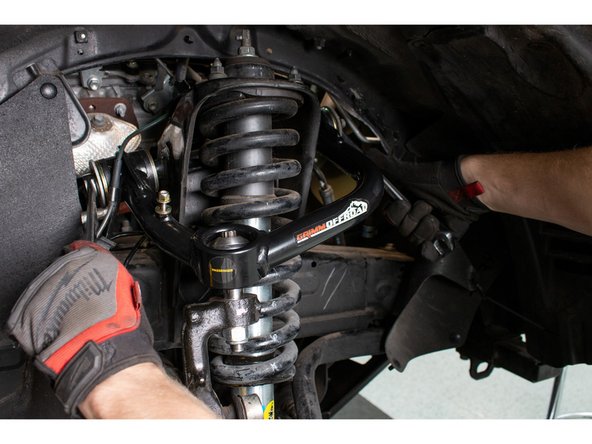

Install the Grimm OffRoad Upper Control Arms onto the vehicle. Note the orientation of the arms, the uniball should be closer to the rear of the vehicle.

-

Re-install the long upper control arm pivot bolt from the opposite side, rear of the vehicle towards the front, with one of the supplied washers on each side of each upper control arm bushing.

-

It will be necessary to remove the splash guards and with a 12mm socket/wrench, remove the brake hard line bracket bolt and slightly bend the brake hard lines out of the way to get the pivot bolt in.

-

Grease the zerk fittings until grease is visibly coming out of the bushings.

-

-

-

Pivot the tapered stem so that it lines up with the tapered hole in the spindle. Push the upper control arm downward so the tapered pin engages the spindle.

-

Take care when inserting the tapered pin into the spindle to not damage the threads on the pin. If you cannot re-orient the pin to line it up, do not force it into the spindle.

-

A second option is to remove the control arm and pin assembly from the frame and install the tapered pin into the spindle first, then use the leverage from holding the control arm to re-orient the pin and line up the mounts at the frame.

-

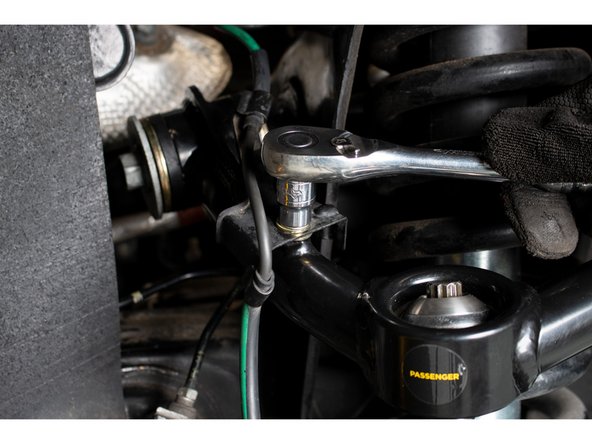

Use a 7/8" socket/wrench to fasten the supplied washer and nylock nut onto the tapered pin to get it to seat properly.

-

Do not use an impact wrench for this step!

-

If the pin spins, you may use the upper 12 point cap screw to prevent it from spinning.

-

Torque the new 9/16" nut to 75 lb-ft [120 N-m].

-

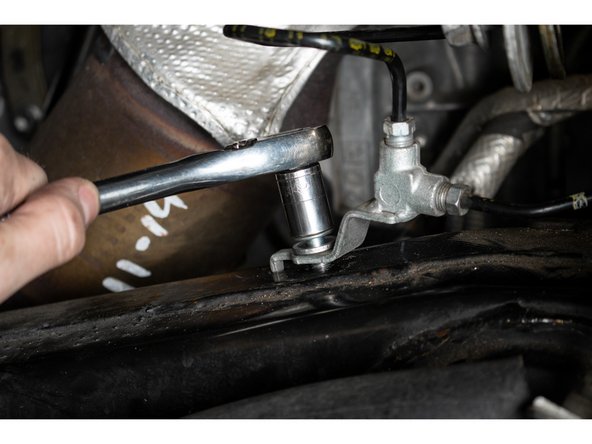

Torque the long upper control arm pivot bolt to 85 lb-ft of torque [115 N-m]. (Crows foot wrench may be necessary)

-

-

-

Re-install the ABS lines onto the stud on the Grimm OffRoad upper control arms.

-

-

-

Re-install wheels and put vehicle back on the ground.

-

Torque lug nuts to factory spec.

-

Remove the 1/2-20 12 point cap screws from the top of the uniballs. Apply provided threadlocker to the threads, and re-install.

-

Torque 12 point cap screws to 90 lb-ft [122 N-m]

-

Verify all hardware has been torqued.

-

Have vehicle professionally aligned.

-

-

-

If the 10019 Billet Upper Control Arm Cap Set was purchased, they can be installed now.

-

Re-check all bolt torques after the first 100 miles, and after every trip offroad.

-

Uniballs benefit from basic maintenance. Keep them clean and use a Teflon based dry lube to maximize their service life.

-

Grease the control arm bushings periodically, especially after wet or dusty trips.

-

When regreasing the upper control arm bushings the upper control arm bolt must first be loosened. After regreasing and purging the old grease, the upper control arm bolt can be retorqued.

-

Installation is Complete!

Installation is Complete!