Introduction

This guide will walk through the correct installation procedure for the Grimm OffRoad JL and JT ARB Twin Compressor Bracket. When the ARB Twin Compressor is in use, it is always recommended to leave the engine running.

Consumer Warning

All Grimm OffRoad products must be installed by a competent and qualified individual in accordance with the installation instructions intended for the product. Incorrectly installed products will void any warranties and may result in damage to the product or damage to the vehicle it was installed on. Read any provided instructions or guides and watch any available videos before attempting installation. If there are any questions, please contact Grimm OffRoad before starting installation.

Many products require the vehicle be properly raised and supported off the ground. The installer is responsible for confirming that this may be done in a safe manner and the correct equipment is available to perform the installation. Grimm OffRoad installation instructions assume the installer is able to properly and safely lift the vehicle.

Vehicles that have been modified will not perform the same as a stock vehicle. It is incumbent upon the owner of the vehicle to be aware of the differences the modifications will make to the driving characteristics of the vehicle. These may include (but are not limited to): changes in handling, braking, rollover angle, incompatibilities with the factory anti-lock braking systems, stability control systems, or traction control systems.

Supporting Parts

This Grimm OffRoad product is designed to be used in conjunction with an ARB Twin Compressor (Specifically the CKMTA12 ). It is important to review and familiarize yourself with the instructions provided with the compressor before beginning installation.

Tools

Parts

- Controls Plate

- Heat Shield

- Compressor Mounting Plate

- Spacer Plate

- Air Filter Relocation Hose (Long)

- Air Filter Relocation Hose (Short)

- High Pressure Stainless Steel Air Line

- Control Harness

- Air Filter Relocation Fitting × 4

- JIC4 Fitting × 2

- M6x1.0 20mm Long Hex Head Bolt × 3

- 5/16 Flat Washer

- M6x1.0 Nylock Flange Nut

- Zip Tie × 10

- ARB Twin Air Compressor Part CKMTA12 (Required)

- Ring Terminal, 6ga, M8 Stud Size (Required) × 3

- Mopar Body Clips 68526185AA (Optional) × 12

Video Overview

-

-

Verify that all parts shown in the pictures are present.

-

Three 6 gauge M8 stud size ring terminals are required to connect the ARB Twin Compressor to the vehicle's battery.

-

-

-

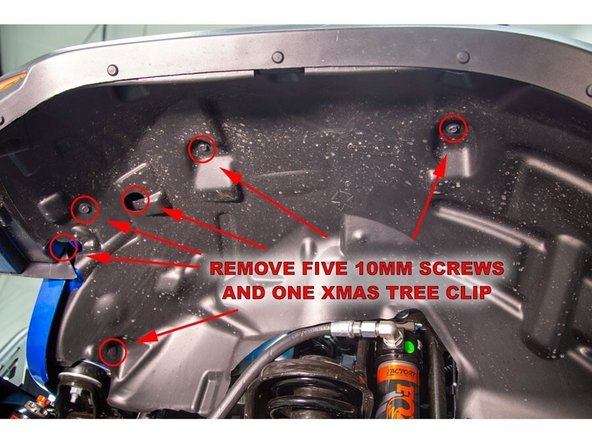

Remove the five fender liner screws with a 10mm socket.

-

Remove the push pin at the front of the inner fender.

-

Start at one end of the flare and pull out, away from the vehicle (pull hard!) to remove the flare.

-

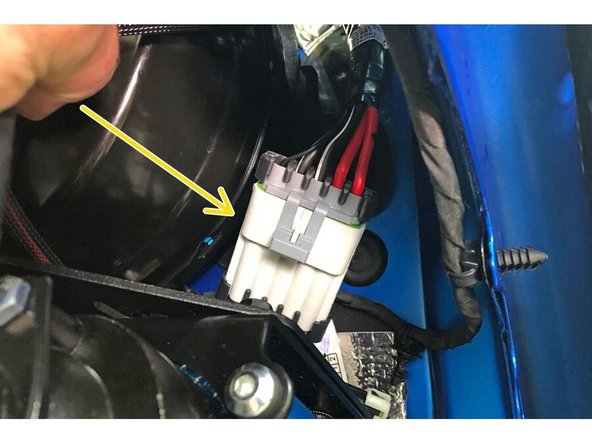

Disconnect the side marker light wire harness by first pulling the red tab out, then separating the connectors.

-

-

-

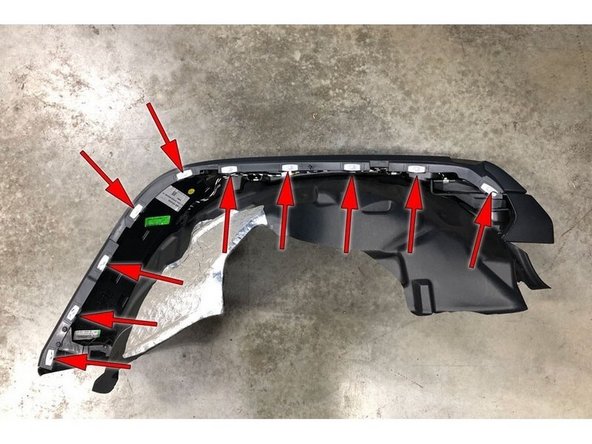

There are ten retaining clips on the backside of the flare. These clips may be damaged during disassembly. Replacement clips are available from Jeep dealers, part number 68526185AA.

-

-

-

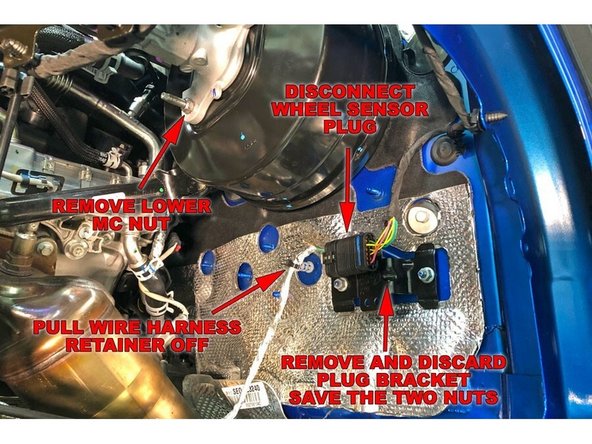

This step pertains to the 3.6L Pentastar engine only. Skip to Step 5 if you have the 2.0L Turbo engine.

-

On the firewall, disconnect the wheel sensor plug.

-

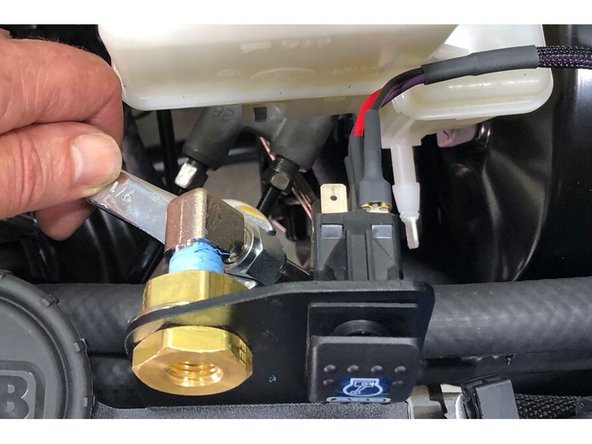

Remove the lower master cylinder nut with a 13mm socket or wrench.

-

Remove the two nuts holding the wheel sensor plug bracket with a 10mm socket or wrench. Save the nuts, as they will be used later.

-

Discard the wheel sensor plug mounting bracket

-

Cut the zip-tie holding the wire harness to the stud directly under the brake booster. Pull the wire harness retainer off the stud and relocate it to the stud above the original plug location. Use a new zip tie to secure the harness to the retainer as shown.

-

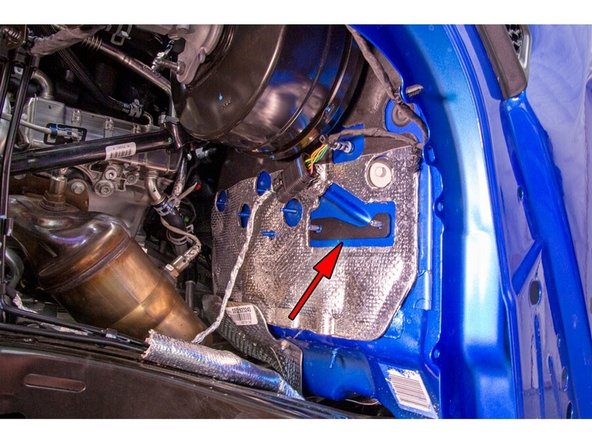

Install the Grimm OffRoad Spacer Plate on the mounting bracket studs as shown.

-

-

-

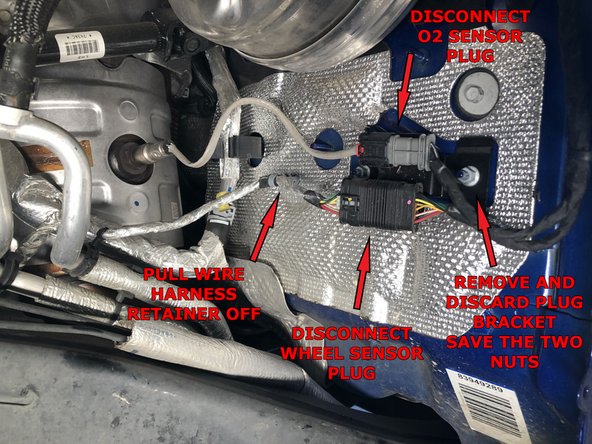

This step pertains to the 2.0L Turbo engine only. Skip to Step 6 if you already completed Step 4.

-

On the firewall, disconnect the wheel sensor and O2 sensor plugs.

-

Remove the lower master cylinder nut with a 13mm socket or wrench.

-

Remove the two nuts holding the plug bracket with a 10mm socket or wrench. Save the nuts, as they will be used later. Discard the plug mounting bracket.

-

Cut the zip-tie holding the wire harness to the stud directly under the brake booster. Pull the wire harness retainer off the stud and discard.

-

Trim the plastic clip that holds that coolant line against the firewall. This clip will interfere with the compressor's heat shield if not removed.

-

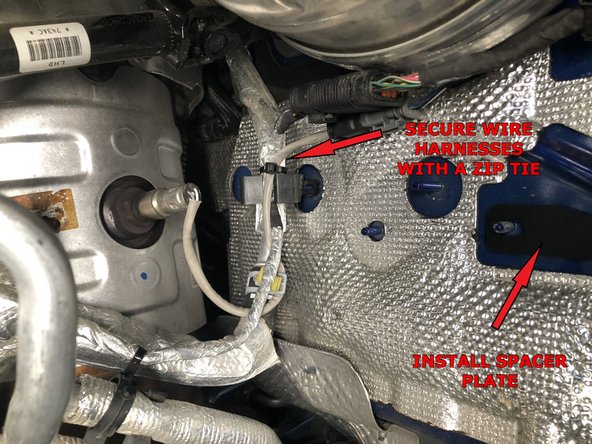

Use a new zip tie to secure the two wire harnesses to the coolant line as shown.

-

Install the Grimm OffRoad Spacer Plate on the mounting bracket studs as shown.

-

-

-

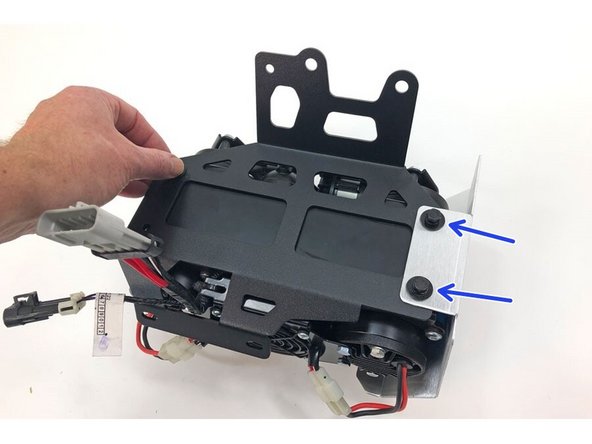

With the mounting holes of the ARB Twin compressor facing up, set the Grimm OffRoad Compressor Bracket into the Compressor, sliding the wiring harness though the large hole in the bracket as shown.

-

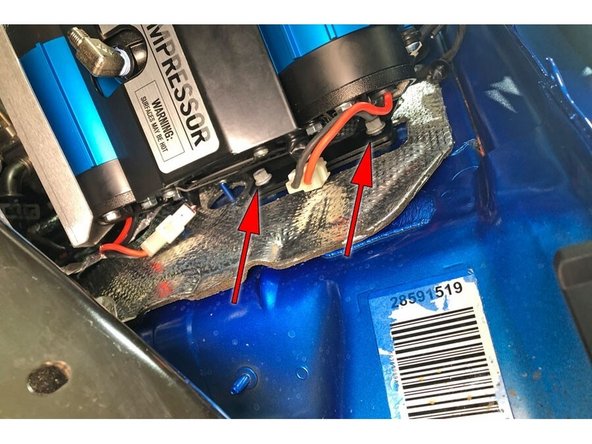

Install the Grimm OffRoad Heat Shield on to the right hand side of the compressor using the ARB bolts, washers, and nuts that came with the compressor.

-

Torque mounting hardware to 5 lb-ft [6 Nm].

-

-

-

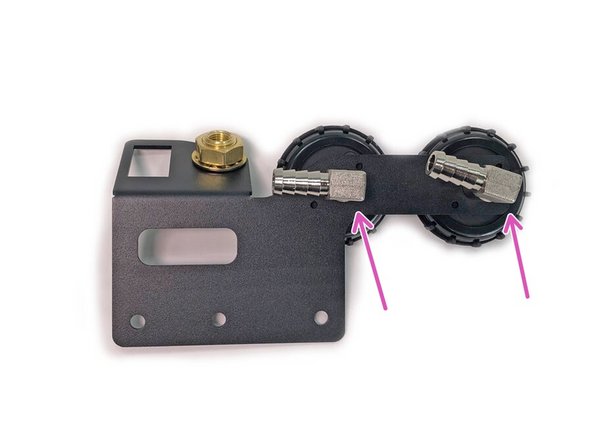

Install the two 1/4” NPT x 1/2” barb 90° fittings into the inlet ports on the ARB Twin Compressor. Use thread sealant on the NPT threads and clock the barb fittings as shown in the picture.

-

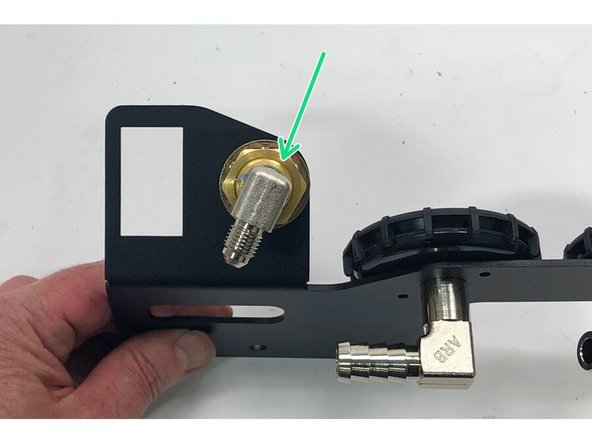

Install one of the 1/4” NPT x JIC4 90° fittings into the outlet post of the ARB compressor. Make sure to use thread sealant on the NPT thread and orient the fitting as shown.

-

Note that NPT fittings are tapered fittings and must not be overtightened. If you can't get the fittings to point the correct direction, it is recommended to remove, use a couple additional wraps of Teflon tape, then reinstall.

-

-

-

Install the compressor assembly onto the lower MC stud and the two firewall studs with the previously installed Grimm OffRoad spacer.

-

Wrangler and Gladiator models will use different mounting bracket holes for the lower MC stud.

-

The extra bolt holes provided in the top of the compressor bracket allow mounting of an ARB Manifold (Part # 171503), allowing the connection of multiple air lockers to a single compressor. Additional wiring is required.

-

Reinstall the OE nuts onto the firewall studs to secure the bottom of the Grimm OffRoad compressor mounting bracket. There is not much clearance, you will need to pull the compressor bracket away from the firewall about 1/4” to get the nuts on. Tighten with 10mm wrench.

-

Torque to 8 lb-ft [11 Nm].

-

Reinstall the lower master cylinder nut.

-

Torque to 13 lb-ft [18 Nm].

-

-

-

The ARB Twin Compressor comes with two wire harnesses. The large gauge harness with the fuse blocks is the main power harness and will be used to power the compressor. The other harness is the control harness and is replaced by the included Grimm OffRoad control harness.

-

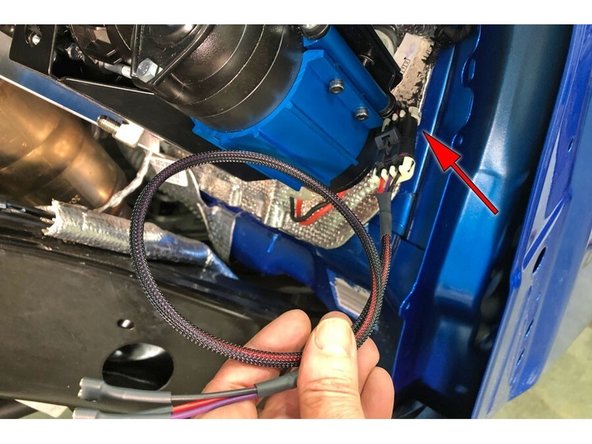

Plug the supplied Grimm OffRoad wire harness into the smaller of the two ARB Air Compressor plugs.

-

Plug the ARB power harness into the matching plug on the ARB compressor, route the wire up over the brake booster, along the firewall to the battery. Use zip ties to anchor the wire harness along the firewall. Connecting the power terminals will be covered later.

-

-

-

Install the supplied filter relocation hoses onto the barb fittings on the compressor. The longer of the two hoses connect to the innermost fitting, the shorter connects to the outer fitting.

-

These lines simply press-on and do not need any additional clamps.

-

Route the air hoses up between the brake booster and the inner fender structure.

-

-

-

Install the ARB Compressor Filters on to the leg of the Grimm OffRoad controls plate as shown.

-

Thread the two 1/4” NPT x female barb fittings onto the ARB filter nipples and tighten by hand. Match the alignment of the barbed fittings as shown in picture above.

-

The ARB filter housing is plastic; the threads can strip out easily. DO NOT OVER-TIGHTEN!

-

Install the 1/4” NPT x JIC4 90° elbow into the back of the bulkhead fitting on the switch bracket. Use thread sealant on the NPT threads and match the alignment of the fitting to the picture.

-

-

-

This step pertains to the 3.6L Pentastar engine only. Skip to Step 13 if you have the 2.0L Turbo engine.

-

Remove the fender bolt shown with a 10mm wrench/socket.

-

Place the provided 5/16" flat washer over the hole to the right of the fender bolt removed.

-

Push hoses from compressor onto the barb fittings on the back side of the air filters.

-

Install the Grimm OffRoad Controls Panel using the three provided M6 bolts.

-

Use a 10mm socket/wrench to torque hardware to 7 lb-ft [9 Nm].

-

-

-

This step pertains to the 2.0L Turbo engine only. Skip to Step 14 if you already completed Step 12.

-

The 2.0L Turbo engine has a mini fuse/relay box that needs to be relocated to make room for the Grimm OffRoad Controls Panel.

-

Remove the painted fender bolt and both bolts securing the fuse/relay box with a 10mm wrench/socket.

-

Relocate the fuse/relay box up above the brake booster and secure with the existing flanged nut and the M6 x 1.0 included flange nut.

-

Use a 10mm socket/wrench to torque hardware to 7 lb-ft [9 Nm].

-

The fuse/relay box mounting bracket may need to be bent down slightly to prevent any interference with the hood when closed.

-

Jump back to Step 12 and finish mounting the Grimm OffRoad Controls Panel.

-

-

-

Be absolutely sure that you hook up this switch correctly according to the diagram in the first image. If wired incorrectly, you can short power directly to ground and damage the wiring in the compressor itself. ARB will not warranty your compressor if this happens.

-

Route the Grimm OffRoad Control Harness through the switch hole in the Controls Plate.

-

Plug the wires into the back of the ARB compressor switch. The BLACK wire goes to the top terminal, the RED wire goes to the center terminal and the PURPLE wire goes to the lower terminal.

-

To install the switch, push the switch into the Controls Plate until it snaps into place.

-

-

-

Install one end of the included Stainless Steel Pressure Hose on to the previously installed fitting on the compressor.

-

Install the other end of the included Stainless Steel Pressure Hose on to the brass bulkhead fitting on the Controls Plate.

-

The Stainless Steel Pressure Hose uses flared fittings and does not need any type of thread sealant.

-

Install 1/4" NPT male air chuck of preference (not included, we recommend ARB hose kit # ARB171302 which includes the ARB0740112 NPT air chuck). Make sure to use thread sealant on the NPT threads.

-

-

-

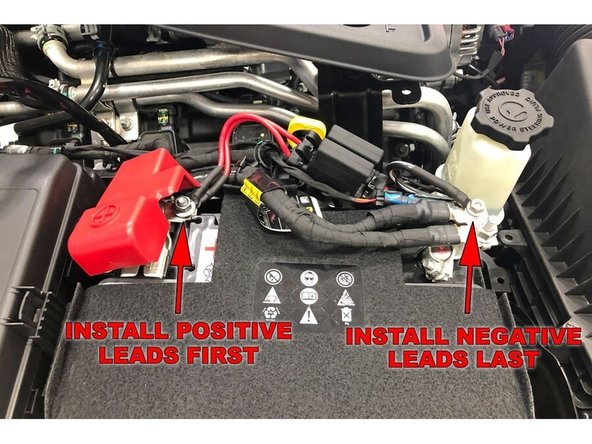

To finish the install, connect the ARB compressor harness power leads directly to the battery according to the ARB Twin Compressor Installation Guide.

-

Three 6 gauge M8 stud size ring terminals are needed to connect the ARB Twin Compressor Harness to the battery terminal ends. M8 ring terminal ends are required and do not come with the ARB compressor harness.

-

-

-

Toggle the compressor switch to the on position. The compressor should turn on for a short period of time then turn off.

-

The fan on the ARB Twin Compressor will continue to run until the switch is turned off.

-

-

-

Re-install fender flare, replacing any retaining clips broken during removal.

-

Reconnect the side marker light wire harness connector and push the red locking tab in.

-

Re-install the five screws using a 10mm socket/wrench and press the push pin back into place.

-

Torque hardware to 7 lb-ft [9 Nm].

-

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.