Introduction

This guide will walk through the correct installation procedure for the Grimm OffRoad JK UD60 Brake Line Kit. This kit includes front and rear brake lines, so these instructions detail both the front and rear installation.

Note: Due to the highly modified nature of most Jeeps with Ultimate Dana 60 Axles, your installation may look different than shown here. How the brake lines are routed and secured may change from Jeep to Jeep.

Consumer Warning

All Grimm OffRoad products must be installed by a competent and qualified individual in accordance with the installation instructions intended for the product. Incorrectly installed products will void any warranties and may result in damage to the product or damage to the vehicle it was installed on. Read any provided instructions or guides and watch any available videos before attempting installation. If there are any questions, please contact Grimm OffRoad before starting installation.

Many products require the vehicle be properly raised and supported off the ground. The installer is responsible for confirming that this may be done in a safe manner and the correct equipment is available to perform the installation. Grimm OffRoad installation instructions assume the installer is able to properly and safely lift the vehicle.

Vehicles that have been modified will not perform the same as a stock vehicle. It is incumbent upon the owner of the vehicle to be aware of the differences the modifications will make to the driving characteristics of the vehicle. These may include (but are not limited to): changes in handling, braking, rollover angle, incompatibilities with the factory anti-lock braking systems, stability control systems, or traction control systems.

-

-

Verify that all parts shown in the picture are present.

-

-

-

These brake lines are best to install with the suspension fully extended on a vehicle lift or on jack stands. This way you can route and secure the brake lines and wheel speed sensors in a manner that prevents them from being over-extended.

-

It is advised to read the instructions thoroughly before beginning. Brake fluid will begin leaking when the stock brake lines are removed so it is best to be prepared and work quickly to connect the new brake lines.

-

-

-

Unclip the wheel sensor wire from clips on the brake line. Remove any zip ties that may have been installed.

-

Remove the hard line nut from the factory brake line bracket where it mounts to the frame using a 12mm flare nut wrench. As soon as the nut is loosened, brake fluid will start leaking. Make sure to have a drain pan in place before loosening the nut.

-

Remove the factory brake line bracket from the frame using a 10mm socket or wrench.

-

-

-

Remove the banjo bolt at the brake caliper with a 15mm wrench/socket. As soon as the bolt is loosened fluid will start leaking. Make sure to have a drain pan ready before loosening the bolt.

-

-

-

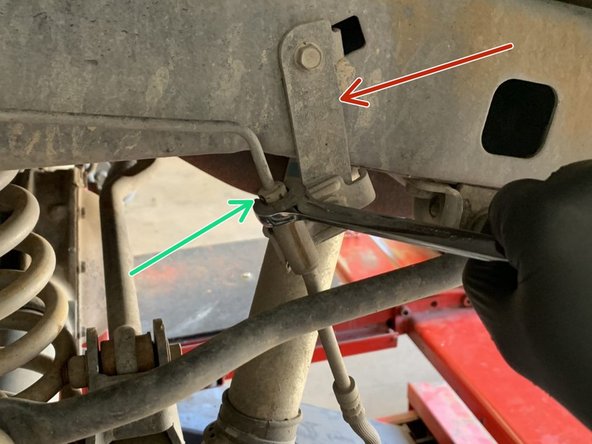

Install a new Grimm OffRoad bracket in place of the stock bracket. Re-use the factory bolt. Position the bracket so that is is parallel to the ground and perpendicular to the hard line. Tighten the bolt with a 10mm wrench/socket.

-

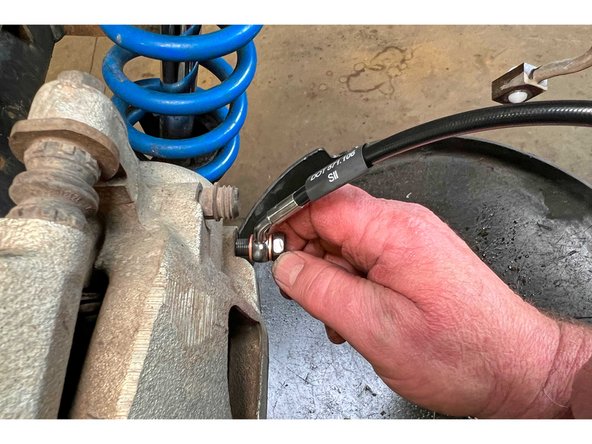

Install the Dana 60 banjo bolt in the Grimm OffRoad brake line. Use a new copper crush washer on each side of the brake line fitting.

-

Bolt the brake line to the caliper and torque to 23 lb-ft [31 Nm].

-

-

-

Insert the Grimm OffRoad brake line up through the newly installed brake line bracket on the frame and secure with the provided clip.

-

Thread the factory hard line nut into the Grimm OffRoad brake line.

-

Using a 12mm flare wrench and a 19mm wrench tighten the nut. Torque to 14 lb-ft [19 Nm].

-

-

-

Repeat steps for the other side of the vehicle.

-

Droop the suspension and cycle the steering lock to lock to make sure the brake line will not bind or interfere with any other components. Zip tie the wheel speed sensor line to the brake line.

-

At this point the front brake line installation is complete.

-

If only installing front brake lines, bleed the brakes according to the Factory Service Manual. If the rear lines are also to be installed at this time, proceed to Step 8.

-

-

-

The installation instructions show an aftermarket brake line relocation bracket. Installation is the same with or without the brackets.

-

Remove the hard line nut from the factory brake line bracket where it mounts to the frame using a 12mm flare nut wrench. As soon as the nut is loosened, brake fluid will start leaking. Make sure to have a drain pan in place before loosening the nut.

-

Remove the factory brake line bracket from the frame using a 10mm socket or wrench.

-

-

-

Remove the banjo bolt at the brake caliper with a 15mm wrench/socket. As soon as the bolt is loosened fluid will start leaking. Make sure to have a drain pan ready before loosening the bolt.

-

-

-

If you are keeping your brake lines in the factory locations on the frame, install a new Grimm OffRoad bracket in place of the stock bracket. Re-use the factory bolt. Position the bracket so that it is perpendicular to the hard line as shown. Tighten the bolt with a 10mm wrench/socket.

-

Alternatively, it is common to relocate the upper brake lines inside the frame to protect them. The Grimm OffRoad bracket will not be used if they are relocated inside the frame.

-

Install the Dana 60 banjo bolt in the Grimm OffRoad brake line. Use a new copper crush washer on each side of the brake line fitting.

-

Bolt the brake line to the caliper and torque to 23 lb-ft [31 Nm].

-

-

-

Insert the Grimm OffRoad brake line up through the newly installed brake line bracket on the frame and secure with the provided clip.

-

Thread the factory hard line nut into the Grimm OffRoad brake line.

-

Using a 12mm flare wrench and a 19mm wrench tighten the nut. Torque to 14 lb-ft [19 Nm].

-

-

-

Repeat steps for the other side of the vehicle.

-

Fully droop the suspension out to verify that the brake lines are long enough and not interfering with any components.

-

At this point the rear brake line installation is complete.

-

Bleed the brakes according to the Factory Service Manual.

-

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.