Introduction

This guide will walk through the correct installation procedure for the Grimm OffRoad Toyota Tacoma ARB Twin Compressor Mounting Bracket Kit. When the ARB Twin Compressor is in use, it is always recommended to leave the engine running.

Consumer Warning

All Grimm OffRoad products must be installed by a competent and qualified individual in accordance with the installation instructions intended for the product. Incorrectly installed products will void any warranties and may result in damage to the product or damage to the vehicle it was installed on. Read any provided instructions or guides and watch any available videos before attempting installation. If there are any questions, please contact Grimm OffRoad before starting installation.

Many products require the vehicle be properly raised and supported off the ground. The installer is responsible for confirming that this may be done in a safe manner and the correct equipment is available to perform the installation. Grimm OffRoad installation instructions assume the installer is able to properly and safely lift the vehicle.

Vehicles that have been modified will not perform the same as a stock vehicle. It is incumbent upon the owner of the vehicle to be aware of the differences the modifications will make to the driving characteristics of the vehicle. These may include (but are not limited to): changes in handling, braking, rollover angle, incompatibilities with the factory anti-lock braking systems, stability control systems, or traction control systems.

Supporting Parts

This Grimm OffRoad product is designed to be used in conjunction with an ARB Twin Compressor (Specifically the CKMTA12 ). It is important to review and familiarize yourself with the instructions provided with the compressor before beginning installation.

We recommend also pairing with ARB’s 171302 Pump Up Kit which includes the required air hose coupling and fill up hose. Alternatively, ARB’s 0740112 air hose coupling or similar can be used.

Tools

Parts

- Compressor Mount Assembly

- Compressor Mount Fender Bracket

- JIC4 Fitting (90 degree) × 2

- Control Harness

- High Pressure Stainless Steel Air Line

- M6x1.0 20mm Serrated Flange Hex Screw × 5

- 5/16 Flat Washer × 2

- M6x1.0 Nylock Flange Nut × 2

- M8x1.25 Nylock Flange Nut × 2

- Zip Tie × 10

- ARB Twin Air Compressor Part CKMTA12 (Required)

- Ring Terminal, 6ga, M8 Stud Size (Required) × 3

-

-

Verify that all parts shown in the pictures are present.

-

Three 6 gauge M8 stud size ring terminals are required to connect the ARB Twin Compressor to the vehicle's battery.

-

-

-

Locate the Grimm OffRoad Fender Bracket and three of the M6-1.0x20mm hex screws.

-

This bracket will be installed using existing bolt holes on the passenger (right side) inner fender.

-

Install the hardware and use a 10mm socket/wrench to torque hardware to 7 lb-ft [9 Nm]

-

If no ABS module is present, the vehicle's horn may be located here and will need to be relocated. See Step 3.

-

-

-

If no ABS Module is present and the vehicle's horn is mounted here, relocate the horn to the rear bolt hole and hang the horn bracket's locating tab off the back of the Fender Bracket.

-

Install the M6-1.0x20mm screws and use a 10mm socket/wrench to torque to 7 lb-ft [9 Nm]

-

-

-

Install the 90 degree 1/4” NPT x JIC4 fitting into the back of the bulkhead fitting on the Compressor Mounting Bracket Assembly using a 9/16" open end wrench. Use thread sealant on the NPT threads.

-

Note that NPT fittings are tapered fittings and must not be overtightened. If you can't get the fittings to point the correct direction, it is recommended to remove, use a couple additional wraps of Teflon tape, then reinstall.

-

Note that a 1" open end wrench can be used on the opposite side to prevent the bulkhead fitting from spinning while installing the NPT fitting.

-

Slide the ARB switch into the Compressor Mounting Bracket Assembly until it snaps into place, noting proper orientation.

-

-

-

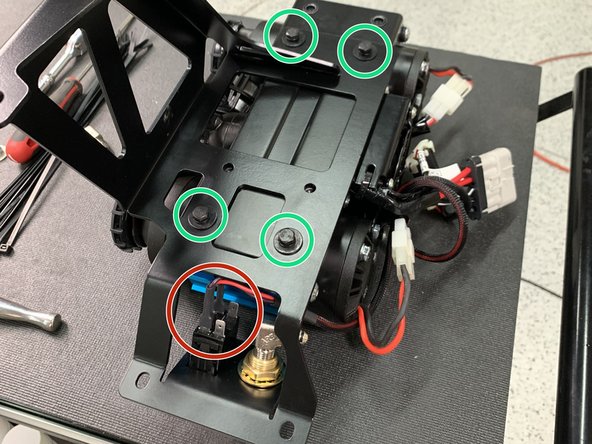

With the mounting holes of the ARB Twin compressor facing up, set the Grimm OffRoad Main Bracket onto the Compressor oriented as shown.

-

Secure the compressor onto the Grimm Offroad Compressor Mounting Bracket using the ARB supplied 6mm hardware with a 10mm socket/wrench.

-

Torque mounting hardware to 7 lb-ft [9 Nm].

-

Be absolutely sure that you hook up this switch correctly according to the diagram in the second image. If wired incorrectly, you can short power directly to ground and damage the wiring in the compressor itself. ARB will not warranty your compressor if this happens.

-

Plug the wires from the Grimm OffRoad supplied switch wire harness into the back of the ARB compressor switch. The BLACK wire goes to the top terminal, the RED wire goes to the center terminal and the PURPLE wire goes to the lower terminal.

-

Connect the other end of the switch harness into the compressor plug.

-

-

-

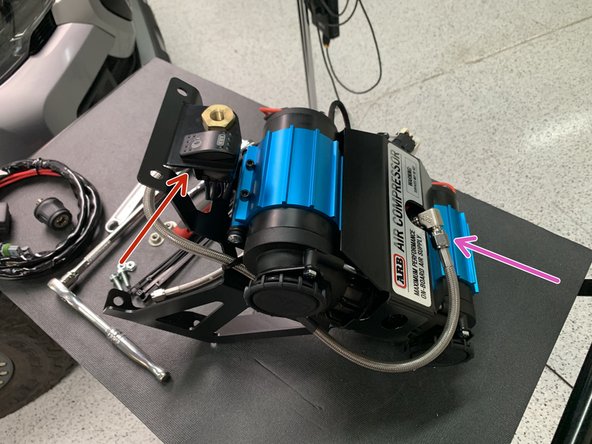

Install the 1/4” NPT x JIC4 90° fitting into the ARB compressor manifold cap using a 9/16" open end wrench. Make sure to use thread sealant on the NPT thread and orient the fitting as shown.

-

Note that NPT fittings are tapered fittings and must not be overtightened. If you can't get the fittings to point the correct direction, it is recommended to remove, use a couple additional wraps of Teflon tape, then reinstall.

-

Install one end of the included Stainless Steel Pressure Hose on to the previously installed NPT fitting on the Compressor Mounting Bracket using a 9/16" open end wrench.

-

Install the other end of the included Stainless Steel Pressure Hose on to the previously installed NPT fitting on the compressor.

-

The Stainless Steel Pressure Hose uses flared fittings and thread sealant is not required.

-

Secure the Stainless Steel Pressure Hose with an included zip tie.

-

-

-

Loosen the hose clamp securing the intake tube to the airbox lid with a 10mm socket/wrench. Remove the airbox lid and filter and place to the side.

-

Remove the two M8 bolts inside of the airbox securing it to the inner fender with a 12mm socket/wrench.

-

Remove the M8 bolt on the outside of the airbox securing it to the inner fender and remove the two nuts securing the ABS Module with a 12mm socket/wrench.

-

Remove the airbox.

-

-

-

Install the Compressor Bracket Assembly using the two bolts for the ABS Module and the inner fender bracket installed earlier.

-

Use two of the provided M6-1.0x20mm hex screws with nylock flange nuts to secure the Compressor Bracket Assembly to the inner fender.

-

Use a 10mm socket/wrench to torque the hardware to 7 lb-ft [9 Nm].

-

Replace the ABS Module nuts removed earlier.

-

If ABS Module is not present, secure the Main Compressor Bracket with the two provided M8-1.25 nylock nuts and 5/16" flat washers.

-

Use a 12mm socket/wrench to torque the hardware to 14 lb-ft [19 Nm].

-

-

-

Reinstall the airbox using the 3 screws removed earlier: one behind the airbox and two inside the airbox.

-

Use a 12mm socket/wrench to torque the hardware to 14 lb-ft [19 Nm].

-

Tighten the hose clamp securing the airbox lid to the intake tube with a 10mm socket/wrench.

-

The air hose coupling can be installed into the bulkhead fitting. We recommend using ARB's 0740112 Air Hose Coupling which is included in their 171302 Pump Up Kit.

-

-

-

To finish the install, connect the ARB compressor harness power leads directly to the battery according to the ARB Twin Compressor Installation Guide.

-

Three 6 gauge M8 stud size ring terminals are needed to connect the ARB Twin Compressor Harness to the battery terminal ends. (Red/Positive - Yellow/Negative) M8 ring terminal ends are required and do not come with the ARB compressor harness.

-

Route the ARB power harness from the battery to the compressor and connect it to the plug on the ARB Compressor.

-

Use zip ties as needed to secure the power harness.

-

-

-

Toggle the compressor switch to the on position. The compressor should turn on for a short period of time then turn off.

-

The fan on the ARB Twin Compressor will continue to run until the switch is turned off.

-

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.

Installation is complete!

With any modified vehicle, or any vehicle used offroad, it is a good idea to check bolt torques periodically and visually inspect components regularly.

![Install the hardware and use a 10mm socket/wrench to torque hardware to 7 lb-ft [9 Nm]](https://d3t0tbmlie281e.cloudfront.net/igi/grimmoffroad/lTZ3rkt4U6QPuDs2.medium)

![Install the M6-1.0x20mm screws and use a 10mm socket/wrench to torque to 7 lb-ft [9 Nm]](https://d3t0tbmlie281e.cloudfront.net/igi/grimmoffroad/4eMIGhYCFJCMQr2n.medium)

![Use a 12mm socket/wrench to torque the hardware to 14 lb-ft [19 Nm].](https://d3t0tbmlie281e.cloudfront.net/igi/grimmoffroad/QAQFhMZT32xHa5sH.medium)